A Practical Guide to Flat Roofs

Flat Roofs and Their Practical Appeal

Flat roofs are a defining feature in UK construction, offering sleek, cost-effective solutions for various building types. Ideal for home extensions, garages, and green roofs, they combine functionality with aesthetic appeal, making them a popular choice in urban and suburban settings. Their minimalist design complements modern architecture, while features like internal gutters or slight gradients ensure effective drainage. This guide explores flat roof installation essentials, including materials, processes, and benefits that make them a smart choice for UK homeowners and businesses.

Why Flat Roofs Are a Smart Choice

Flat roofs offer practical advantages that cater to a variety of residential and commercial needs. Their adaptability allows them to accommodate innovative features, while their cost-effective nature ensures they remain a popular choice. With proper installation and drainage solutions, flat roofs provide durability and efficiency, making them ideal for the UK’s architectural and climatic demands.

Cost-Effectiveness:

Flat roofs are a budget-friendly roofing option. They use fewer materials and require less labour to install compared to pitched roofs, lowering overall costs. Maintenance is also more affordable due to their accessible structure, which simplifies inspections and repairs.

Space Efficiency:

Flat roofs make efficient use of space by creating opportunities for practical or aesthetic enhancements. They are ideal for rooftop gardens, seating areas, or patios, adding functionality and value to a property without additional structural changes.

Sleek Aesthetics:

The clean lines and minimalist design of flat roofs enhance the appearance of modern architecture. Their understated appeal integrates seamlessly into both urban and suburban settings, giving properties a contemporary edge.

Versatility:

Flat roofs are designed to support a range of modern features, such as solar panels and water collection systems. With effective drainage solutions, they remain functional and durable, even in areas with heavy rainfall, ensuring long-term reliability.

Choosing the Right Materials for Flat Roofs

Selecting the right material is essential to ensure your flat roof delivers long-lasting performance, especially in the UK’s varied climate. Each flat roofing material offers unique strengths and challenges, with factors like durability, moisture resistance, and maintenance requirements playing a crucial role. The best choice will depend on your project’s specific needs, budget, and long-term objectives, ensuring a roof that stands the test of time. Below, we examine the most popular flat roofing materials, highlighting their key advantages, challenges, and suitability for different applications.

EPDM (Ethylene Propylene Diene Monomer)

EPDM rubber is a practical and modern flat roofing solution widely used for its durability and adaptability. Its synthetic composition ensures reliability across a range of climates, making it a trusted option for both residential and commercial properties in the UK.

Advantages:

- Highly durable and weather-resistant, with the ability to withstand extreme weather conditions, including hail, wind, and UV radiation.

- Requires minimal maintenance, reducing long-term costs. Its synthetic rubber composition resists cracking, splitting, and peeling.

- Remains flexible in extreme temperatures, accommodating building movements and thermal expansion without compromising integrity.

- Lightweight and easy to install, simplifying the process on various roof types and reducing labour costs.

- Long lifespan of up to 30–50 years based on industry projections and current performance standards.

Disadvantages:

- Susceptible to punctures caused by sharp objects or debris, especially during installation or from foot traffic.

- Repairs, while often straightforward, may require specialist tools and knowledge for optimal results.

In summary: EPDM rubber is a reliable, weather-resistant roofing solution that excels in the UK’s varied climate. Its exceptional durability, flexibility, and low maintenance requirements make it a practical choice for flat roofs, especially where resilience to temperature fluctuations is essential. Proper installation ensures maximum lifespan and optimal performance.

GRP Fibreglass (Glass Reinforced Plastic)

GRP fibreglass is a contemporary roofing solution known for its strength, seamless finish, and versatility, making it suitable for various property types and architectural styles. Its joint-free application ensures dependable performance and complements a variety of modern roofing needs.

Advantages:

- Provides a seamless, joint-free finish, significantly reducing the risk of leaks and ensuring complete waterproofing.

- Lightweight and strong, suitable for structures with weight constraints while offering high durability.

- Ideal for regions with heavy rainfall, preventing water ingress and related damage.

- Aesthetically versatile, with options for coloured or textured finishes to complement architectural designs.

- Long lifespan of 20–30 years with proper care, and some roofs last even longer.

Disadvantages:

- Can become brittle in extreme cold without appropriate additives or protective measures, potentially leading to cracks or damage.

- Requires precision during installation, including correct resin mixing and layering, to prevent leaks and ensure durability.

- Unsuitable for frequent foot traffic without additional reinforcement as it can be prone to surface damage.

In summary: GRP fibreglass provides a seamless, waterproof roof finish, making it ideal for modern properties. Its lightweight strength, design versatility, and durability in wet climates make it a reliable choice for flat roofs. While precise installation is crucial, its long-term reliability and aesthetic flexibility enhance its overall appeal.

Torch-On Felt (Modified Bitumen)

Torch-on felt is a prevalent choice for flat roofing due to its practicality and cost-effectiveness. Its reliable waterproofing and affordability make it a consistent choice for cost-conscious projects.

Advantages:

- Cost-effective and reliable, making it a popular option for budget-conscious projects.

- Provides effective waterproofing through its layered design, creating a sealed system that resists leaks and moisture.

- Weather-resistant, performing well in various climates and withstanding UV rays and temperature fluctuations.

- Straightforward to install when carried out by trained professionals, ensuring efficient application and strong adhesion.

Disadvantages:

- Shorter lifespan of 10–20 years compared to modern materials.

- Requires regular maintenance, including inspections of seams and addressing wear to ensure optimal performance.

- Safety precautions during installation are essential due to the use of open flames, posing fire hazards.

In summary: Torch-on felt offers an affordable and dependable waterproofing solution for flat roofs. Its layered design ensures resilience against leaks and harsh weather. Though it has a shorter lifespan and requires regular maintenance, it remains a practical choice for budget-conscious projects.

PVC Membrane (Polyvinyl Chloride)

PVC single-ply roofing membranes are renowned for their durability, flexibility, and reliable performance, making them a trusted choice for modern properties. Their chemical resistance and long-lasting protection make them a dependable option for flat roofs.

Advantages:

- Highly flexible and durable, accommodating building movements and thermal expansions without compromising integrity.

- Resistant to chemicals, UV radiation, and fire, making it ideal for industrial and commercial settings.

- Suitable for both residential and commercial flat roofs, offering a lightweight and adaptable solution.

Disadvantages:

- Higher initial cost compared to some alternatives, though their durability often offsets this over time.

- Requires professional installation to ensure seam integrity and optimal performance.

In summary: PVC roofing membranes stand out for their robust protection, chemical resistance, and long-term durability. Their flexibility and reliability make them an excellent investment for industrial and commercial settings, particularly where strong, watertight roofing solutions are essential.

TPO Membrane (Thermoplastic Polyolefin)

TPO membranes are recognised for their durability, affordability, and versatility, making them a popular choice for flat roofs in both residential and commercial settings. Their lightweight construction and robust protection make them a practical solution for a variety of projects.

Advantages:

- Lightweight and flexible, simplifying installation and accommodating building movements.

- Resistant to chemicals, UV radiation, and weathering, ensuring durability across various climates.

- Generally, more affordable than premium materials like PVC, offering a cost-effective solution.

Disadvantages:

- Lifespan varies from 15–30 years depending on material quality and environmental conditions.

- Requires precise installation by professionals to ensure seam integrity and performance.

- Regular inspections are needed to maintain reliability and address potential issues early.

In summary: TPO roofing membranes provide a cost-effective, lightweight, and durable flat roofing solution. Their adaptability and resilience across different climates make them a practical choice for both residential and commercial projects, especially where budget considerations are a priority.

BUR (Built-Up Roofing)

BUR is a traditional and time-tested solution for flat roofs, consisting of multiple layers of bitumen alternated with reinforcing fabrics, topped with a protective surface layer such as gravel, a reflective coating, or layers compatible with green roof installations. Its multi-layered design ensures robust waterproofing and long-term reliability.

Advantages:

- Proven durability, lasting 20–30 years with proper maintenance.

- Multi-layered design offers superior waterproofing, preventing leaks and water damage.

- Can accommodate green roof installations, combining environmental benefits with structural reliability.

- Requires minimal maintenance once installed, with regular inspections ensuring continued performance.

- Suitable for high-traffic areas, with gravel or aggregate layers providing additional wear resistance.

Disadvantages:

- Heavier than modern single-ply materials, requiring strong structural support and potentially increasing costs.

- Installation is labour-intensive and time-consuming, leading to higher labour costs and project timelines.

- Protective layers like gravel may need occasional replenishment to maintain effectiveness.

In summary: BUR provides a traditional and robust flat roofing solution, leveraging its multi-layered design for superior waterproofing and wear resistance. Its proven durability makes it ideal for high-traffic areas and green roofs, but the weight and complex installation may limit its suitability for some projects.

Liquid-Applied Membranes

Liquid-applied membranes are increasingly popular for flat roofs in the UK due to their adaptability, ease of application, and ability to create a seamless, watertight surface. Their flexibility and uniform application deliver excellent protection for a wide range of roofing needs.

Advantages:

- Seamless application eliminates vulnerabilities associated with seams or joints in traditional systems.

- Flexible and adaptable, ideal for roofs with complex shapes or detailing.

- Superior waterproofing and UV resistance ensure long-term protection.

- Can be applied over existing materials, reducing costs and disruption.

- Versatile for residential, commercial, and green roof applications.

Disadvantages:

- Surface preparation must be meticulous to ensure proper adhesion and performance.

- Higher initial cost than some traditional options, though long-term savings can offset this.

- Some systems require multiple layers or extended curing times, potentially prolonging installation.

- Regular inspections are recommended to address wear, particularly in high-traffic areas.

In summary: Liquid-applied membranes offer a seamless and flexible roofing solution for complex flat roof designs. Their superior waterproofing and adaptability across applications make them increasingly popular. While installation requires meticulous preparation, their durability and versatility make them a smart long-term investment.

Sustainability in Flat Roofs

Flat roofs not only offer practical benefits but also present opportunities for sustainable building solutions. By choosing eco-friendly materials, integrating energy-efficient features, and considering long-term environmental impacts, flat roofs can contribute significantly to reducing your property’s carbon footprint. Let’s explore how flat roofs contribute to sustainability through eco-friendly materials, energy-efficient features, and long-lasting durability.

Eco-Friendly Materials:

Many flat roofing options, such as PVC and TPO membranes, are recyclable and designed with environmentally conscious manufacturing processes to reduce their impact. Liquid-applied membranes are another eco-friendly choice, as they can be applied directly over existing roofing materials, reducing waste generated from removal and disposal. Opting for these materials supports sustainability without compromising on performance.

Green Roofs:

Flat roofs are ideal for green roofs, which create a layer of vegetation that offers natural insulation, regulates building temperature, and improves air quality. These living roofs support local biodiversity by providing a habitat for plants and small wildlife. Additionally, green roofs manage stormwater runoff by absorbing rainwater, reducing strain on urban drainage systems, and helping to mitigate flooding risks in built-up areas.

Energy Efficiency:

Incorporating high-performance insulation, such as PIR or XPS boards, enhances a roof’s thermal performance, reducing heat loss during winter and heat gain in summer. This improvement significantly lowers energy consumption and utility bills. Solar panels can be seamlessly integrated into flat roofs, converting sunlight into renewable energy and further reducing a property’s carbon footprint, making flat roofs a smart choice for energy-conscious homeowners.

Durability and Lifespan:

Durable materials like EPDM and GRP fibreglass offer exceptional longevity, often lasting decades with minimal maintenance. This longevity reduces the need for frequent replacements, which in turn minimises material waste and conserves resources. By choosing long-lasting materials, property owners can achieve a sustainable roofing solution that balances durability with environmental responsibility.

Essential Materials and Tools for Flat Roof Installation

Successfully installing a flat roof requires the right combination of materials and tools to ensure durability, performance, and longevity. High-quality materials and precise tools work together to provide stability, insulation, and waterproofing for a professional and reliable installation. Below, we outline the key materials and specialised tools that are critical for achieving a durable, high-performance flat roof.

Key Materials

Each material in a flat roof installation plays a specific role in meeting performance standards and maintaining the roof’s integrity over time. Selecting the right materials ensures long-term durability and efficiency.

- Substrates:

OSB boards, plywood, or concrete bases provide a stable foundation for the roofing system.

- Insulation:

High-performance materials like polyisocyanurate (PIR) boards, extruded polystyrene (XPS), or mineral wool improve energy efficiency and prevent condensation.

- Vapour Control Layers (VCL):

Vapour control membranes act as a barrier to prevent warm, moist air from reaching colder surfaces, reducing the risk of condensation.

- Roofing Materials:

Options include EPDM rubber, GRP fibreglass, modified bitumen, PVC membrane, TPO, BUR (built-up roofing), or liquid roofing systems. Each material offers unique advantages suited to different project needs.

- Adhesives and Primers:

Rubber adhesives, bitumen primers, or resins ensure secure bonding of roofing materials to the substrate.

- Fasteners and Tapes:

Screws, nails, seam tapes, and mechanical fasteners provide strong connections and watertight seals.

- Sealants:

High-performance silicone, or polyurethane-based sealants are essential for sealing edges and preventing leaks.

- Edge Trims:

Aluminium or uPVC trims give the roof a clean, professional finish while enhancing durability.

Essential Tools

Specialised tools are vital for achieving accuracy and efficiency during flat roof installation. Each tool serves a specific purpose, ensuring a professional finish and supporting the roof’s durability over time.

- Application Tools:

Rollers, brushes, and trowels ensure smooth application of roofing materials and adhesives.

- Cutting Tools:

Utility knives, scissors, and circular saws are used for precise cutting of insulation boards, membranes, and other materials.

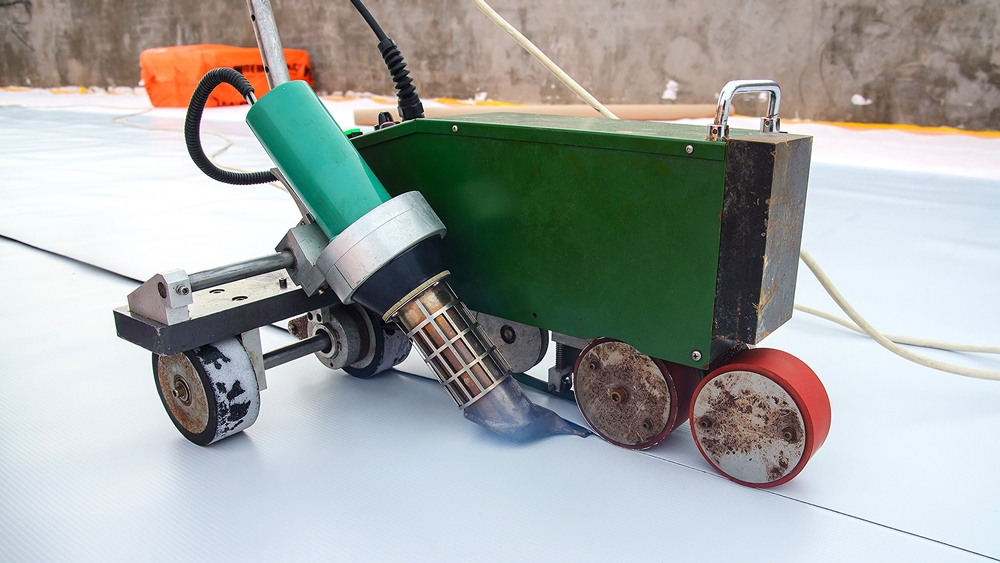

- Heating Equipment:

Propane torches are necessary for torch-on felt installations, while heat-welding tools are used for single-ply membranes like PVC, TPO, and specialised EPDM.

- Inspection Tools:

Water-testing equipment and thermal imaging devices help identify leaks or weak points in the roofing system.

- Safety Gear:

Personal protective equipment such as gloves, goggles, and safety harnesses ensures worker safety during the installation process.

Flat Roof Installation Process

Installing a flat roof involves several crucial steps to ensure durability, performance, and compliance with UK Building Regulations. Here is an overview of the typical process:

Step 1: Planning and Preparation

Proper planning lays the groundwork for a successful flat roof installation. Key considerations include:

- Assess the Structure:

Evaluate the structure to ensure it can support the roofing materials, insulation, and features like green roofs or skylights. Identify and address any existing rot, decay, or structural weaknesses. Reinforce with suitable materials to enhance load-bearing capacity and stability.

- Design Drainage:

Create a slight gradient (minimum 1:40 fall) or plan internal gutter systems to prevent water pooling. Account for potential rainfall volume and determine the most suitable drainage system, such as internal gutters or external drains.

- Ensure Regulatory Compliance (England and Wales):

Ensure the design complies with Building Regulations, covering energy efficiency (Part L), structural safety (Part A), fire safety (Part B), and moisture resistance (Part C). Consult local building control authorities for guidance and ensure proper insulation, ventilation, and load-bearing calculations are included in the design.

- Ensure Regulatory Compliance (Scotland):

Adhere to the Building Standards, addressing energy performance (Section 6), structural stability (Section 1), fire safety (Section 2), and moisture management (Section 3). Consult Scottish building control authorities for advice and refer to the Scottish Building Standards Technical Handbook for detailed requirements.

- Engage Professional Expertise:

Hire qualified professionals to select materials, tools, and techniques. Follow British Standards (e.g., BS 6229:2018) to minimise installation risks, such as inadequate drainage or improper sealing. Choose roofers with relevant accreditations and insurance for quality workmanship and peace of mind.

Step 2: Insulation

Insulation is a crucial component of flat roofs, improving energy efficiency, preventing condensation, and enhancing indoor comfort. Proper insulation reduces heat loss in winter and heat gain in summer, resulting in lower energy bills and a more comfortable living environment.

- Warm Deck Insulation:

The most commonly used and preferred method in modern UK construction, where insulation boards are placed above the roof deck. High-performance materials like polyisocyanurate (PIR) boards or extruded polystyrene (XPS) provide excellent thermal resistance, moisture resistance, and compressive strength, making them suitable for supporting the weight of the roofing membrane.

- Cold Deck Insulation:

A traditional method that is now less common due to its lower energy efficiency and higher risk of condensation. Insulation is positioned below the roof deck, leaving the deck exposed to external temperatures. Adequate ventilation and careful design are critical to avoid condensation. Typical materials include mineral wool or fibreglass rolls.

- Vapour Control Layer (VCL):

A VCL is an essential component in flat roof systems, installed to prevent warm, moist air from reaching colder surfaces, where condensation could compromise the roof’s integrity. It is typically positioned beneath the insulation in warm deck systems or below the deck in cold deck systems. Correct installation without gaps or punctures is crucial to maintain its effectiveness.

Step 3: Laying the Material

The choice of roofing material determines the specific installation method. Below are common flat roofing systems and their application processes:

- EPDM (Ethylene Propylene Diene Monomer):

EPDM membranes are unrolled and laid over a clean, dry, and prepared substrate. Adhesives are evenly applied to secure the membrane, with seams sealed using specialised tapes or adhesives to create watertight joints. Heat-weldable EPDM options are also available and are steadily gaining popularity for their enhanced durability. Once installed, edges are trimmed, and inspections confirm a proper seal and finish. This process results in a durable, flexible roofing system resistant to temperature changes and UV exposure.

- GRP Fibreglass (Glass Reinforced Plastic):

GRP installation begins with preparing the substrate, ensuring it is smooth and primed. A resin coat is applied as an adhesive layer, followed by carefully laying fibreglass matting to cover the surface. Another coat of resin is applied to saturate the matting and bond it securely to the substrate. Finally, a topcoat is applied to create a seamless, weatherproof finish. The curing process solidifies the material, making it suitable for flat roofs with complex geometries.

- Torch-On Felt (Modified Bitumen):

The roof surface is first primed with a bitumen-based primer for better adhesion. Rolls of torch-on felt are unrolled, and a propane torch is used to heat the bitumen backing as the material is rolled out. This process bonds the felt to the substrate and ensures a watertight seal. Multiple layers may be applied for added durability, with overlaps carefully sealed to prevent leaks. Torch-on felt roofing is particularly effective for flat or low-slope roofs.

- PVC Membrane (Polyvinyl Chloride):

PVC membranes are installed over a smooth, clean base prepared to ensure adhesion. The membrane can be secured using mechanical fasteners, adhesives, and heat-welded seams. Heat-welding tools are used along seams to create a durable, watertight bond. The edges are trimmed and sealed, and the surface is inspected for consistency and coverage. PVC membranes are ideal for commercial buildings due to their chemical resistance and flexibility.

- TPO Membrane (Thermoplastic Polyolefin):

TPO membranes are unrolled over the cleaned and prepped roof surface. Proper alignment and tensioning during this stage ensure the membrane lies flat, preventing wrinkles or gaps. The membrane is then secured to the substrate using adhesives or mechanical fasteners. Overlapping sections are fused with heat-welded seams, creating watertight joins. TPO is particularly suitable for large-scale commercial projects due to its affordability and UV resistance.

- BUR (Built-Up Roofing):

The installation of BUR begins with proper cleaning and priming of the roof surface to ensure a strong bond and optimal performance. The process then involves alternating layers of hot bitumen and reinforcing fabrics, such as felts or mats, which can vary to influence performance and durability. A final layer of gravel, reflective coating, or other materials is added to enhance the roof’s functionality, aesthetics, or protection from weathering and UV exposure. This multi-layered system forms a durable, long-lasting waterproof barrier, making it ideal for flat roofs.

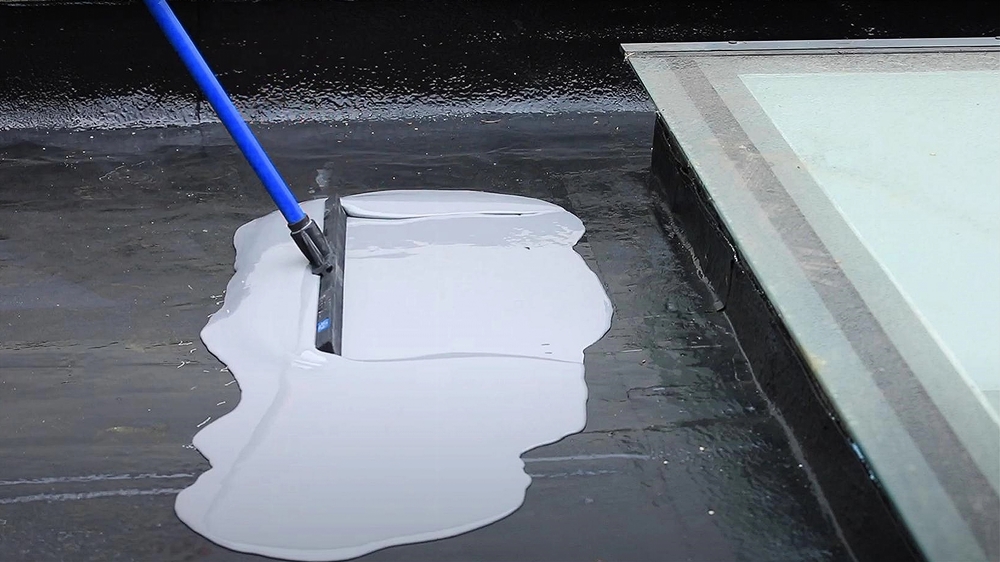

- Liquid-Applied Membranes:

The substrate is cleaned and primed to ensure proper adhesion. The liquid membrane is then applied using a roller, brush, or spray equipment. Multiple coats may be necessary, with adequate curing time between applications to achieve the desired thickness and performance. This seamless, watertight solution is particularly effective for roofs with intricate shapes or as an overlay for existing roofing materials.

Step 4: Finishing Touches

The final stage of a flat roof installation focuses on inspections, aesthetic details, and optional enhancements to ensure the roof performs as intended and complements the building. These include:

- Leak Checks:

Thorough inspections, such as water testing or thermal imaging, identify and address any potential vulnerabilities. Ensuring the roof is completely watertight at this stage reduces the risk of future damage and guarantees long-term performance.

- Aesthetic Details:

Finishing touches, such as durable aluminium or uPVC trims, give the roof edges a polished and professional appearance. These elements enhance visual appeal while adding a layer of durability to protect against weather exposure.

- Optional Features:

Incorporate additional elements like sedum plants for green roofs, rooflights to enhance natural lighting, or solar panels to boost energy efficiency. Proper substrates, reinforcements, and installation techniques are essential to integrate these features seamlessly while preserving the roof’s structural integrity.

Maintenance Tips for Longevity

Proper maintenance is essential for ensuring your flat roof remains durable and effective, avoiding costly repairs and extending its lifespan. By following routine care and maintenance tips, you can safeguard your roof against common issues, keep it performing optimally, and protect your investment for years to come.

Regular Inspections:

Conduct routine inspections, particularly after heavy rainfall or extreme weather. Look for signs of wear and tear, such as cracks, blisters, or punctures in the roofing material. Clearing debris like leaves, twigs, and dirt is vital, as they can trap moisture and accelerate damage to the roof surface.

Drainage Management:

Flat roofs are prone to water pooling, which can compromise their structural integrity over time. Regularly check and clean gutters, downpipes, and drainage outlets to ensure water flows freely. Address blockages promptly to prevent water from accumulating on the roof.

Spot Repairs:

Addressing minor issues early can save you from more significant problems later. If you notice cracks, punctures, or loose seams, schedule repairs as soon as possible. Simple fixes, like resealing joints or patching small holes, can prevent leaks and further damage.

UK Building Regulations and Planning Requirements

Adhering to UK building regulations and planning requirements is essential when installing a flat roof. Planning requirements determine if the project complies with local development guidelines, such as height restrictions or boundary proximity. Building regulations ensure the roof meets safety, efficiency, and durability standards, covering insulation, drainage, and structural support. Together, these ensure your project is compliant and built to last.

Addressing both planning permissions and building regulations is crucial to compliance. Qualified installers can assess your property, implement solutions, and provide documentation for peace of mind. By meeting these requirements, you can ensure your flat roof is reliable, regulation-approved, and aligned with local authority guidelines. To assist with meeting planning requirements and building regulations, the following resources are invaluable:

Planning Portal (England & Wales):

The Planning Portal is a leading online resource for planning and building regulations in England and Wales. It offers comprehensive tools and information to help homeowners, builders, and developers navigate planning requirements for projects like flat roofing. By providing clear guidance on permissions, compliance, and project planning, the portal simplifies the process of achieving legal and regulatory approval. With extensive resources and expert insights, it empowers users to take the necessary steps for a successful and compliant installation.

Scottish Government Building Standards:

For flat roofing projects in Scotland, understanding and adhering to planning permission and building regulations is vital. The Scottish Government Building Standards offers comprehensive advice on topics such as building control, safety, and sustainability. This trusted resource ensures compliance with both local and national regulations, supporting every stage of the project, from initial planning to final completion. It is a reliable reference for successfully managing all regulatory requirements.

Benefits of Hiring Professionals

Hiring professionals for your flat roof installation offers numerous advantages, ensuring every aspect of the project is handled with expertise, precision, and care. From selecting the right materials to avoiding costly mistakes and ensuring long-term reliability, they bring unparalleled value to your project. Let’s explore these key benefits to ensure a successful flat roof installation.

Expertise in Materials and Methods:

Professional roofers bring a wealth of knowledge to help you select the most suitable materials and installation methods for your specific needs. Whether it’s EPDM, GRP fibreglass, or modified bitumen, their expertise ensures a durable and effective solution.

Minimising Errors:

Improper installation can lead to leaks, pooling, or structural damage, resulting in costly repairs and even compromising your roof’s integrity over time. Professionals have the skills and tools to minimise these risks, ensuring the roof is robust, watertight, and built to withstand environmental challenges. Their attention to detail and adherence to best practices add reliability to the installation.

Peace of Mind:

Most reputable companies offer warranties on their work, providing long-term security. Additionally, they often provide ongoing maintenance services, helping your flat roof stay in top condition for years. By hiring professionals, you can trust that your flat roof is installed to the highest standards, offering lasting protection and excellent value for your investment.

Frequently Asked Questions About Flat Roofs

How long does a flat roof last?

The lifespan of a flat roof depends on the type of material and the level of maintenance it receives. EPDM rubber roofs can last 30–50 years, GRP fibreglass roofs typically last around 25 years, and built-up roofing (BUR) can last over 30 years with proper care. Regular inspections and maintenance can significantly extend the lifespan of any flat roof.

How much does a flat roof cost to install?

The cost of installing a flat roof varies depending on the size of the roof, the materials used, and the complexity of the installation. Basic installations using materials like torch-on felt are often more affordable, while high-performance options like GRP fibreglass or EPDM rubber typically come at a higher price. Consulting with a professional can provide a tailored quote based on your specific requirements and budget.

What is the best material for a flat roof in the UK?

The best material depends on your project’s requirements. EPDM rubber is highly durable and cost-effective, GRP fibreglass offers a seamless and aesthetic finish, and PVC membranes are eco-friendly and resilient. For traditional durability, BUR is a proven option. Consulting with a professional can provide a personalised estimate based on your needs and budget.

How often should a flat roof be inspected?

It is advisable to inspect flat roofs at least twice a year, typically during the spring and autumn seasons. Additionally, inspections should be carried out after severe weather conditions to check for damage or pooling water. Regular inspections can uncover small problems early, helping to avoid expensive repairs down the line.

Can I install a flat roof myself?

While it is possible to install a flat roof yourself, professional installation is highly recommended. Flat roof installation requires precision, specialised tools, and knowledge of UK building regulations. Improper installation can lead to leaks, pooling, or structural issues, which can be expensive to fix.

What happens if my flat roof pools water?

Pooling water, or “ponding,” can lead to premature wear, leaks, and structural damage over time. Proper drainage design, such as slight gradients or internal gutter systems, is crucial for preventing this issue. If pooling occurs, consult a professional to address the drainage problem and avoid further damage.

Our Comprehensive Range of Roofing Services

At Northfield Contracts Ltd., we take pride in offering not just exceptional flat roofing services but a full spectrum of roofing solutions to suit every need. Whether you are considering durable tiled roofs, sleek slate options, or innovative green roofs, our team of experienced professionals is ready to assist. From minor repairs to complete installations, we provide tailored services using high-quality materials to ensure your roof is both functional and visually stunning.

Discover more about our extensive roofing services by visiting our comprehensive roofing services page. Let us help you find the perfect solution to elevate your property while delivering lasting protection and style.

Conclusion

Flat roofs offer UK homeowners and businesses a practical, cost-effective, and versatile roofing solution. From their sleek aesthetics and efficient use of space to the wide range of material options, flat roofs are a valuable addition to any property. With proper installation and regular maintenance, they can provide years of reliable performance, even in the face of the UK’s challenging weather conditions.

Ensuring a durable, high-quality flat roof requires expert planning, skilled installation, and adherence to building regulations. Partnering with professionals not only reduces risks but also guarantees a roof that meets your needs while adding value and functionality to your property.

Ready to upgrade to a sleek, cost-effective flat roof?

Contact Northfield Contracts Ltd. today for a free consultation and expert advice on your next roofing project. Let us help you achieve a durable and stylish flat roof solution tailored to your requirements.

Northfield Contracts Ltd. is your number one choice for flat roofing services in Berwick-upon-Tweed, North Northumberland, and the Scottish Borders.

Share this post.

Stay informed.

Your data will be stored and processed in accordance with our Privacy Policy.